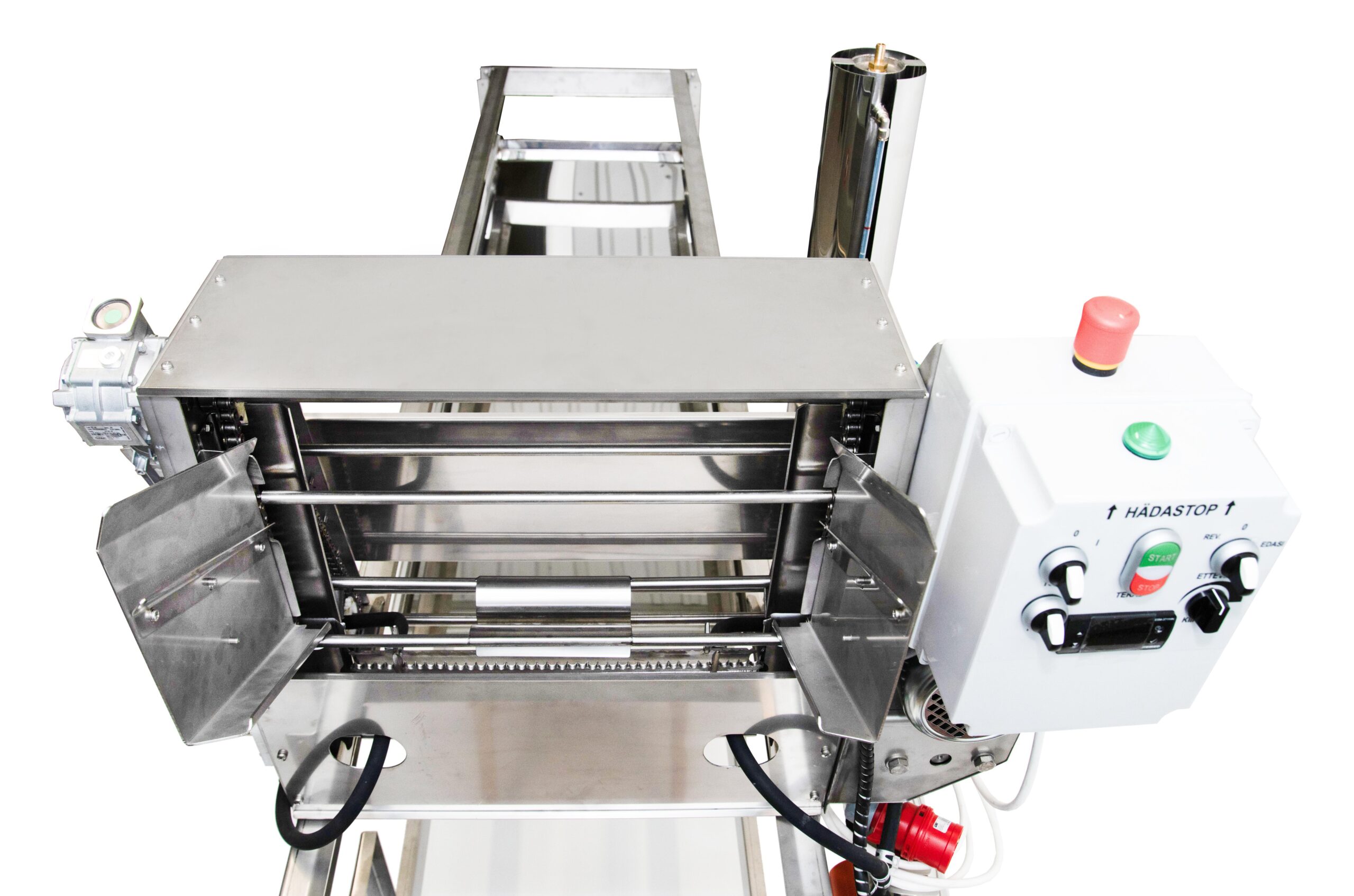

The small uncapping machine is designed to uncap honeycombs using hot cutting knifes.

The uncapping machine is suitable for apiary`s where 50 to 150 bee colonies are managed.

Productivity of the uncapping machine is about 6-10 frames per minute.

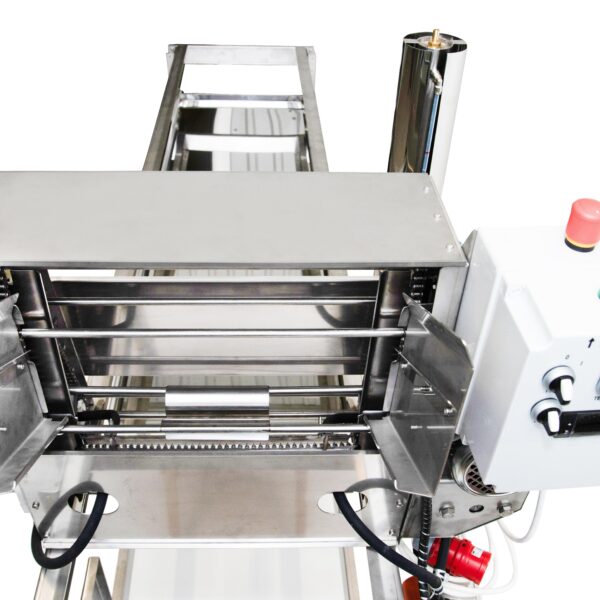

The heating system of the cutting knives is equipped with a 2kW heater which can be controlled by a temperature controller.

Heating system water capacity 5l, circulation of the system is ensured by a circulation pump.

Possibility to adjust the gap between the cutting knives.

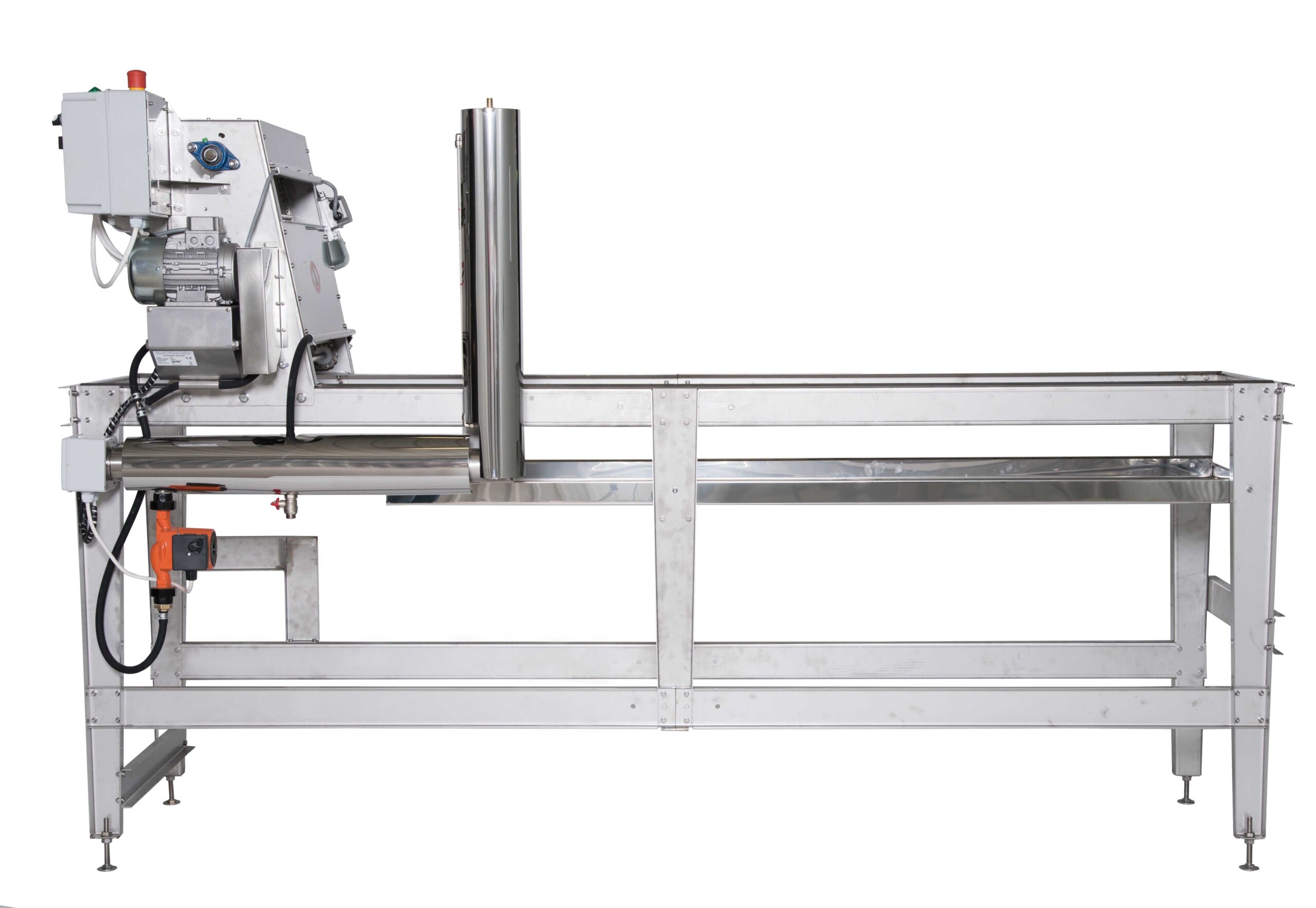

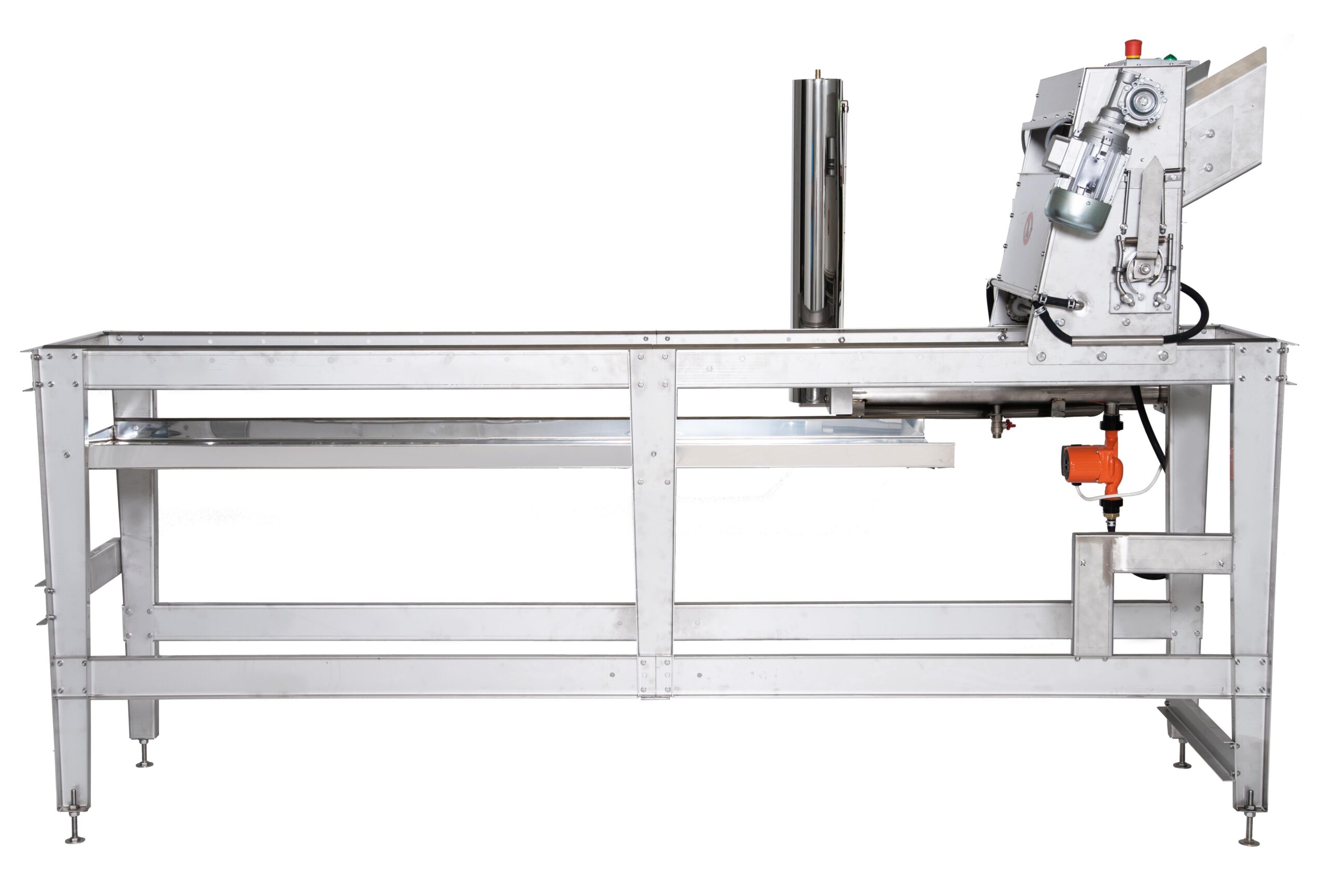

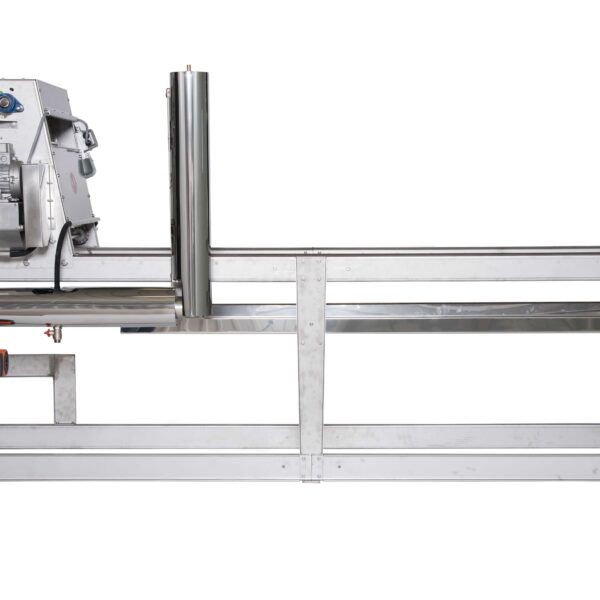

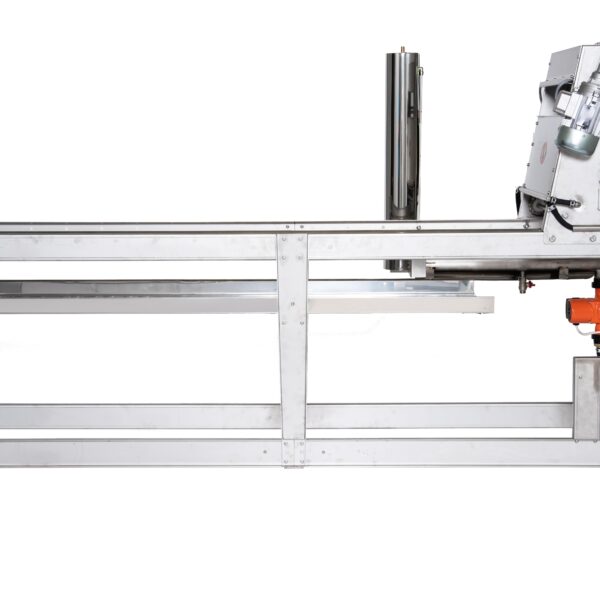

The uncapping machine is on a 2500mm long frame, of which 2000mm is a drainage bath.

Drainage bath capacity 50-56 frames. Using the feed motor, the drain pan is automatically filled with uncapped frames.

These products, produced by Asten Honey production & technology, are suitable for the small uncapping machine: capping extruder, honey pump, honey filter and honey extractor.

By adding these products to the uncapping machine, you have created a small uncapping line solution for your apiary.