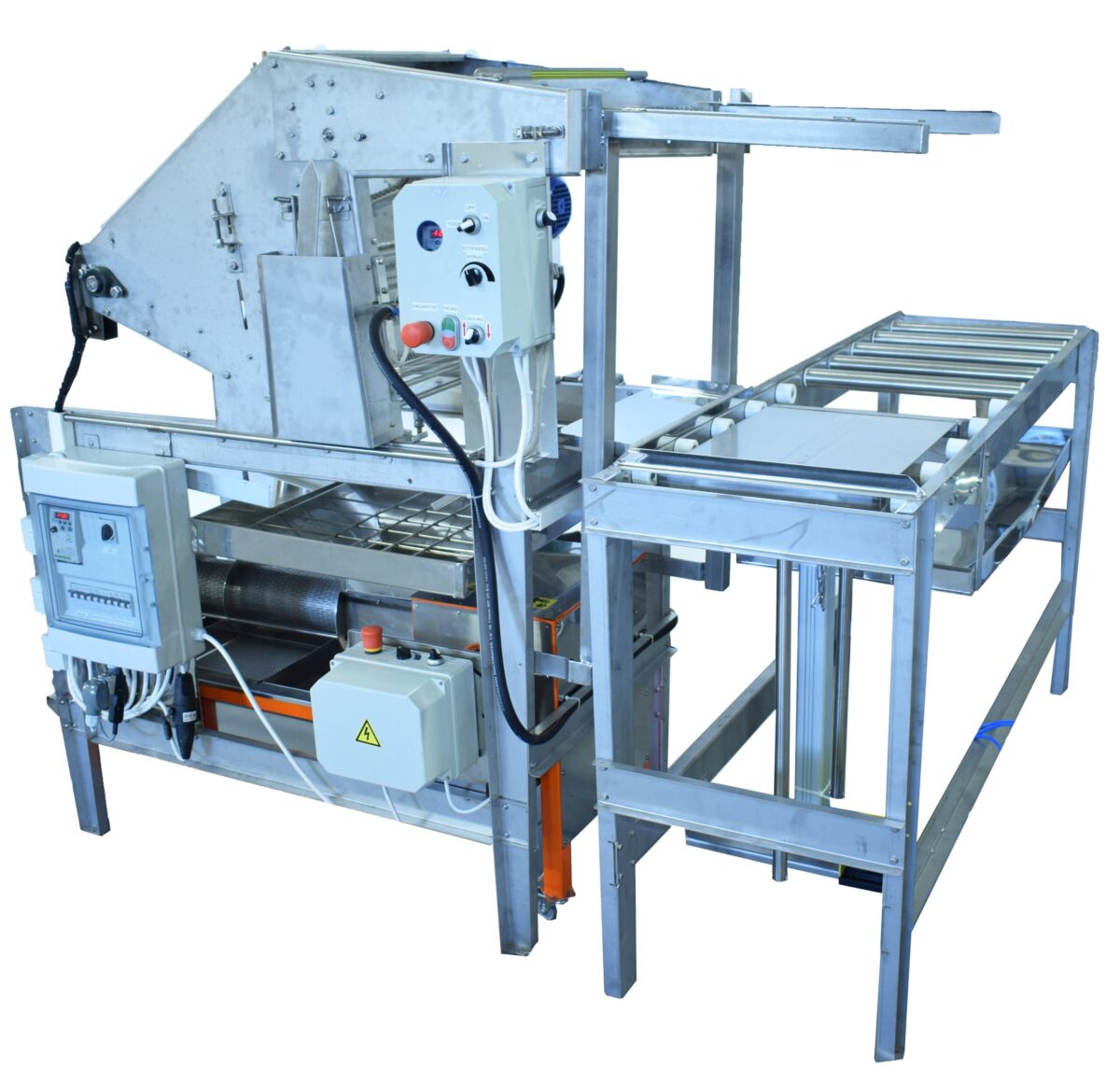

The big uncapping machine is equipped with feeding chains, so it is possible to connect a deboxer to the device.

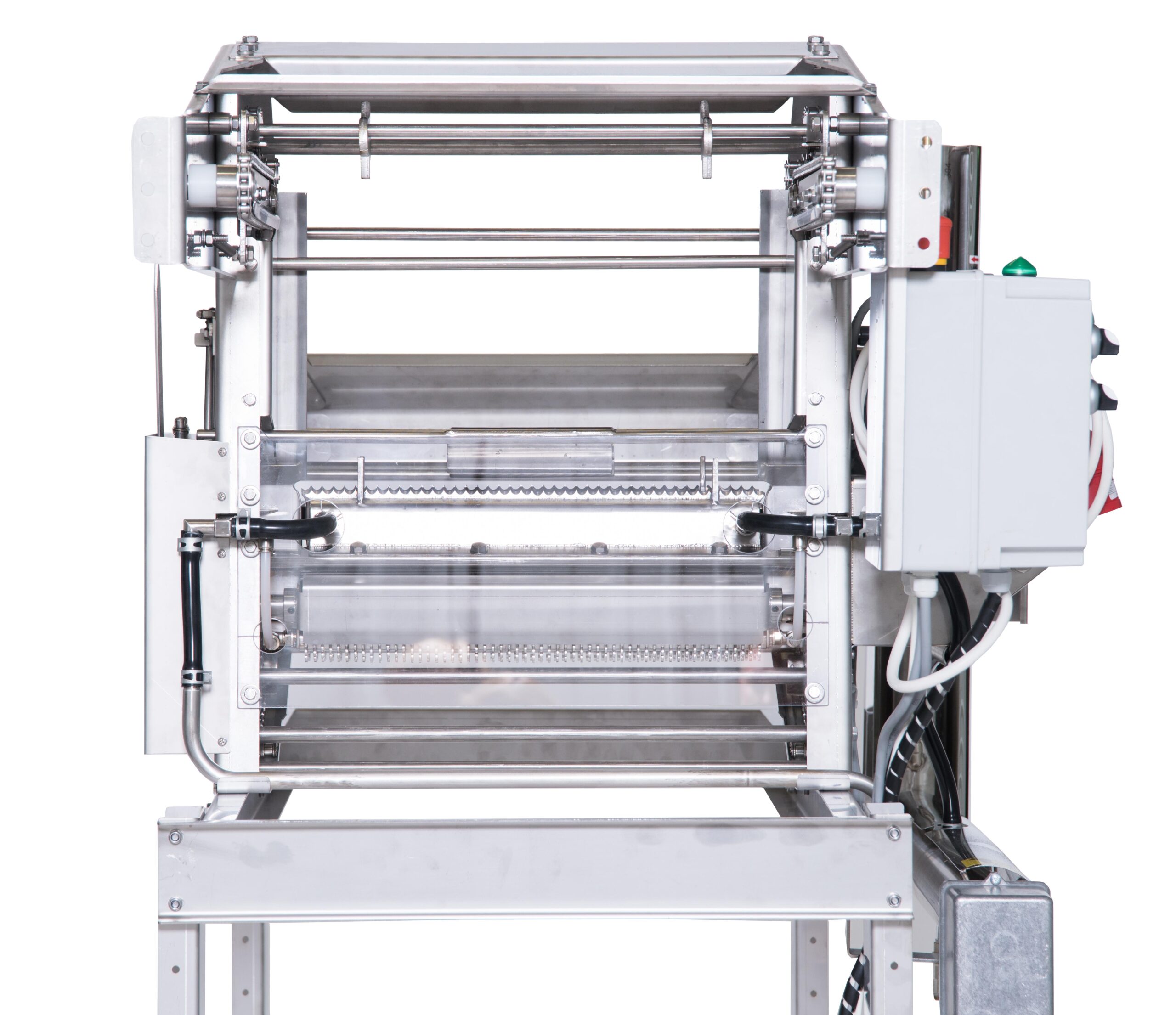

The big uncapping machine is equipped with two cutting knifes and comb loosener system.

The gap between the cutting knives is adjustable.

The cutting knives and the comb loosener system have a closed heating system that works on hot water.

Water capacity in the system 5l, heating is done with a 3kW stainless steel heater, the temperature can be regulated with a temperature controller up to 95 C`.

The big uncapping machine is on a 2500mm long frame, of which 2000mm is a drain bath.

The drainage bath holds 50-56 frames.

The big uncapping machine has a productivity of 6 to 10 frames per minute. Depends on the working speed and the structure of the honey comb.

Using the feed motor, the drain pan is automatically filled with uncapped frames.

These products, produced by Asten Honey production & technology, are suitable for the big uncapping machine: capping extruder, honey pump, honey filter and honey extractor.

By adding these products to the big uncapping machine, you have created a medium uncapping line solution for your apiary.

As the production of honey increases in your apiary, it is later possible to add to the big uncapping machine: first rails (with the mechanism for moving the frames), barrel extractor for 80 frames and rear draining rails.

This way you have created a fully automated line solution.